Do you know what ink type you need for your new printer? Use our extensive guide to find the right ink for the media you are using.

Aqueous Ink

Aqueous inks are water-based and safer to use than other inks because they are non-toxic. It can be either pigment or dye based. Pigment is a chalk-like substance suspended in water, and when the water evaporates the pigment sticks to the surface in the printed pattern.

This ink is best for indoor fine art displays and produces high resolution graphics. It is not UV resistant and will fade in the sun, and it is also not water resistant. Aqueous inks are ideal for small format printing in schools, homes, and offices. They are not generally used for large format graphics because of the lengthy time they take to dry.

Use aqueous inks on porous materials like cardboard and paper, as it will not adhere well to plastic and other substrates. Small businesses and individuals will find these inks perfect for indoor applications and will appreciate this nontoxic ink that produces images with great depth.

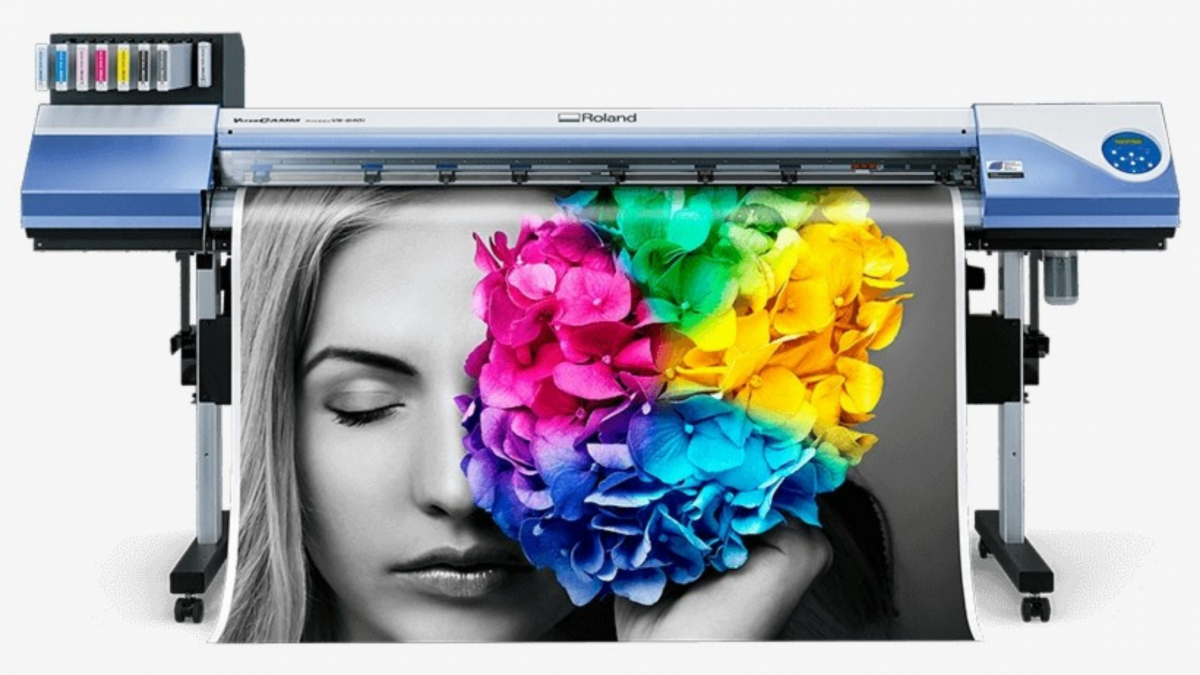

Eco-Solvent Ink

Eco-Solvent inks are environmentally friendly, and don’t produce harmful fumes like heavy solvent inks making them ideal for office settings. They don't last as long outdoors as strong solvent ink, up to 3 years as opposed to 5 years. Cure time can take up to 24 hours, so take that into consideration.

It is highly durable and has good adherence to coated and non-coated surfaces. Eco-solvent inks produce high resolution images that are perfect for billboards and other large format outdoor advertisements. These inks are also cheaper and less harsh on printheads and will extend printer’s life.

Use for indoor and outdoor sign and display, billboard papers, point of sale, self-adhesive vinyls, polypropylene, mesh, and vehicle wraps. The evaporation process can take up to 24 hours.

UV Ink

UV inks dry instantly when exposed to UV light. This speeds up print production as prints are ready much faster and is great for high-volume printers and rush jobs. Instant dry also means no chemicals are released into the air through evaporation which makes this a less toxic option.

With UV ink, printers use less ink because it doesn’t evaporate or become absorbed into the substrate. UV ink prints on almost any substrate and the colors are bright and fade-resistant. It should not be used on substrates that stretch as the ink will crack. Because UV inks are so durable, outdoor media printed with UV inks do not need lamination like latex and solvent inks do.

Use UV inks with a compatible printer that has a built-in curing function. It is best used on hard substrates like wood, plastic, or metal with a flatbed printer because any material that will be rolled will likely crack.

Solvent Ink

Solvent inks use pigments suspended in a compound similar to aqueous inks, but instead of water solvent inks use a volatile organic compound (VOCs) known as solvents. They can be toxic and require a ventilation system.

A less expensive option, solvent inks can be used on uncoated substrates like vinyl and plastic. They are protected from water and UV light and are most commonly used for outdoor application like banners and billboards. These inks dry through rapid evaporation of the solvent, which creates toxic fumes.

This ink type is good for flexible media and favored for vehicle wrap vinyl and decals. Substrates printed with solvent ink are durable and scratch-resistant.

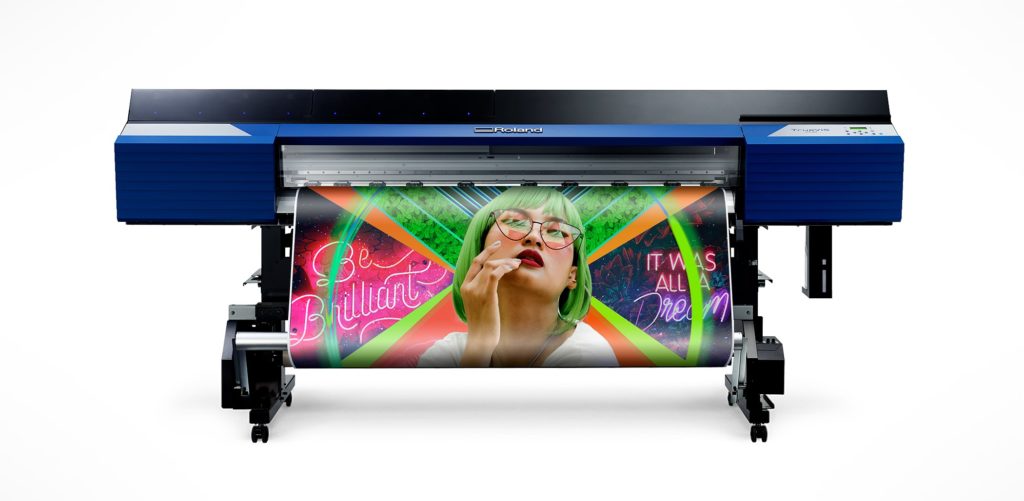

Latex Ink

As one of the newest inks on the market, latex inks are only available from a few suppliers. Latex ink is eco-friendly and a good alternative to solvent inks. Similar to solvent inks, latex inks use pigments suspended in a liquid which adheres to the paper once the liquid evaporates. But unlike solvent inks, latex ink is water based, making it odorless and non-toxic as well as non-flammable.

Latex inks are cured by heat applied to the media and dry almost instantly. Substrates printed with latex inks will last outdoors for up to three years without lamination.

It is used most often for large format outdoor displays, and vehicle wrap vinyl.

Dye-Sublimation Ink

Dye sublimation, also know as dye diffusion inks, are used mostly with heat transfer to apply ink to a substrate like polyester fabric or a solid object. Dye sub inks can be solvent or water based. To create garments with designs, the ink is printed onto a transfer paper, and once dry the transfer paper is applied with heat and pressure onto the substrate. During the process, called dye transfer, the dye sublimates (evaporates) and creates a permanent bond with the fabric.

Another option is dye direct where dye sublimation inks are printed directly onto polyester fabric. After printing, the fabric is run through a heat press to set the ink.

Dye sub inks are used to personalize any number of things like t-shirts and sweatshirts, phone and tablet covers, ceramic mugs, plaques made of plastic, wood, glass, and metal.

Comparison Chart

| Ink Type | Advantages | Disadvantages | Uses |

| Aqueous | Nontoxic Images have great depth | Limited range of substrates Only indoor use, will fade in the sun | Fine art paper, canvas, indoor use |

| Solvent | Fast drying time Abrasion resistant Inexpensive | Very toxic, needs ventilation Requires lamination | Plastic substrates, best for outdoor signage. |

| Eco-Solvent | Less toxic and can be used in enclosed spaces High resolution images Economical Wide range of uses | Long drying time Don’t last as long outdoors | Plastic substrates, best for outdoor signage Canvas, banner, vehicle wraps |

| Latex | Fast drying Resistant to solvents No hazardous vapors Can be used with many substrates | High drying energy consumption Not abrasion resistant on porous materials | Soft signage, wallpapers, vehicle graphics, banners and vinyl |

| UV | Instant dry time Can print on almost anything Bright colors No hazardous vapors | Only indoor use Not waterproof Expensive Can’t use on flexible material | Large format, almost any rigid substrate (not good for flexible substrates or vinyl) |

| Dye Sublimation | Wide color gamut Washable Good for outdoors | Requires transfer press Only compatible with 100% polyester or sublimation coated fabric Can be costly | Garments, ceramics, apparel and promotional items |

Conclusion

Uses the right kind of ink to get the best results. Shop our large selection of HP, Roland, and STS compatible ink. If you need assistance in choosing ink, give us a call at 718-399-3333. Our wide format experts at extension 128 are happy to help! Or you can email us at [email protected].

At S&F News, our mission is to keep you informed on the latest industry trends and tips. Check back often for updates.